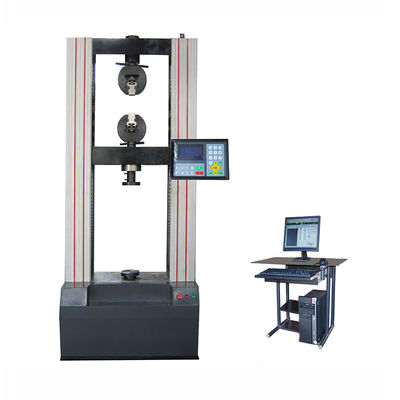

Plastic Processed:

PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, MLLDPE, EPS, PA, Polystyrene, PE, LDPE, EVOH, HDPE/PP, ABS/PP, PE/PP

Condition:

New

Style:

Horizontal

Distance between Tie Bars(Width)(mm):

663mm

Distance between Tie Bars(Height)(mm):

663mm

Mold Height(mm):

240 - 550 mm

Ejector Number:

5

Ejector Stroke(mm):

100 mm

Ejector Force(kN):

77 kN

Theoretical Shot Volume(cm³):

1046 cm³

Injection Rate (g/s):

558 g/s

Machine Type:

Hydraulic

Injection Weight (g):

951 g

Screw Speed (rpm):

1 - 300 rpm

Screw diameter (mm):

70 mm

Screw L/D Ratio:

20

Distance between Tie Bars:

663x663mm

Weight (KG):

13000

Type:

Preform Injection

Place of Origin:

Zhejiang, China

Open Stroke(mm):

510 mm

Model Number:

3880NS

Μάρκα:

SUNBUN

Power (kW):

45 kW

Warranty:

1 Year

Key Selling Points:

Energy saving

Applicable Industries:

Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Construction worksÂ

Showroom Location:

Egypt, Turkey, Brazil, Indonesia, Russia, Morocco, Algeria, Bangladesh, Ukraine

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Other, Pressure vessel, Engine, Gearbox

After-sales Service Provided:

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Turkey, Brazil, Indonesia, Russia, Morocco, Algeria, Bangladesh, Ukraine

Πιστοποίηση:

CE, ROHS

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!